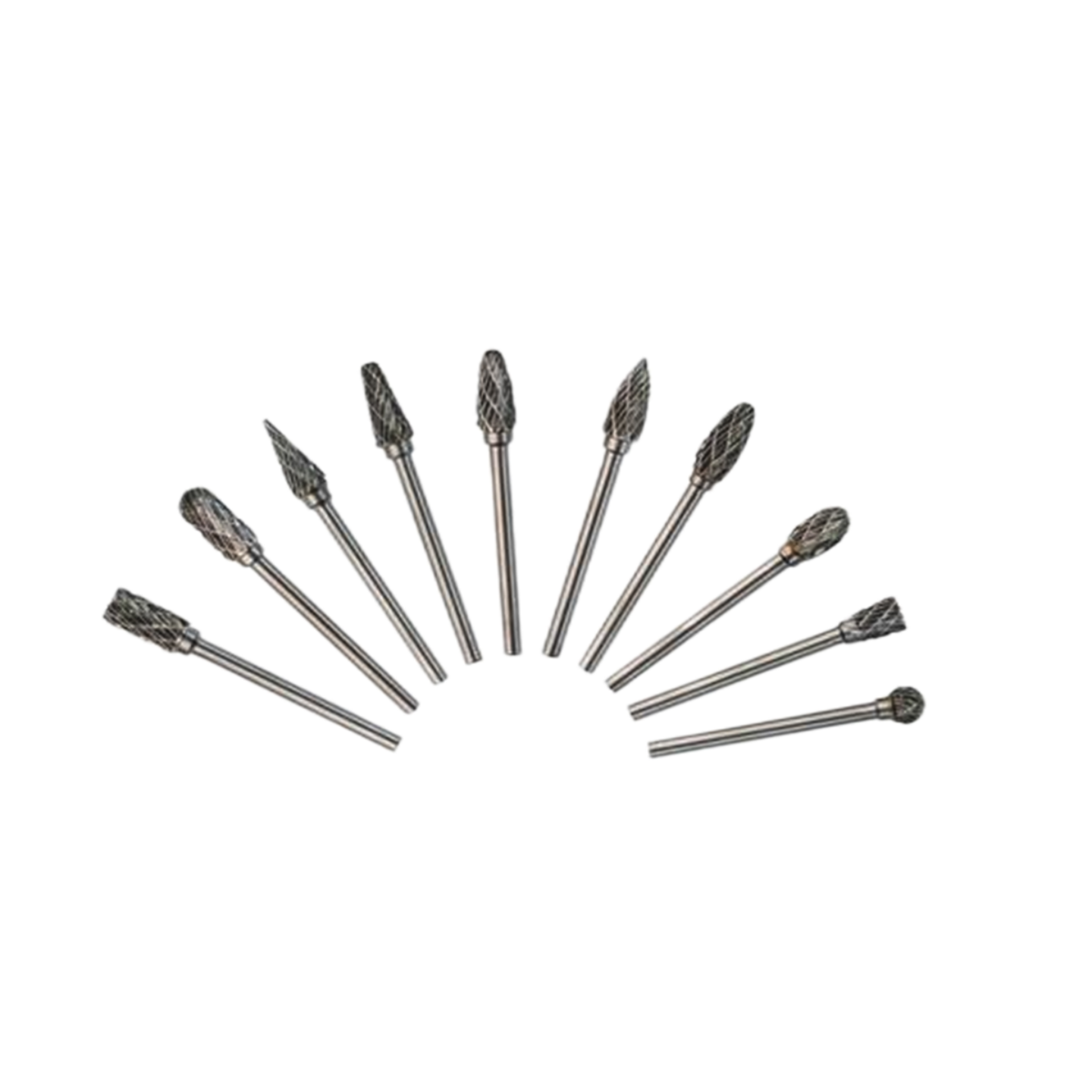

Elehand Carbide Rotary Burrs Grinder Bits for Cutting Metal

Feature

1. Toughened and hardened steel shanks. The combination of premium grade materials for both the shank and head, with the precise production process, results in the creation of a consistent and secure program of tools.

2. Provides rigidity and strength. Material specific designs offer improved performance and up to 50% higher metal removal rates over standard carbide burrs. Prevents bending and reduces vibration, resulting in improved tool life.

Details

Specification:

Elehand Carbide Burrs

Our carbide burr includes a variety of designs and

shapes to offer an ideal option for the majority of applications in all major industry segments.

The types of the blade:

Single Blade, Double Blade, Bastard Blade

The types of shape:

Cylinder shape, Cylinder shape with end mill cut, Cylinder shape with radius end

Ball shape

Oval shape

Tree shape with radius end, tree shape with pointed end

Flame shape

Cone shape

Taper shape

Inverted cone shape

Including the following sizes:

|

Dia.(mm) |

Cut Length |

Shank |

Overall Length |

|

3 |

13 |

3 |

38 |

|

4 |

13 |

4 |

50 |

|

4 |

13 |

3 |

40 |

|

5 |

13 |

3 |

40 |

|

6 |

13 |

3 |

48 |

|

6 |

16 |

6 |

56 |

|

8 |

20 |

6 |

60 |

|

10 |

20 |

6 |

60 |

|

12 |

25 |

6 |

65 |

|

14 |

25 |

6 |

65 |

|

16 |

25 |

6 |

65 |

|

18 |

25 |

6 |

65 |

|

20 |

25 |

6 |

65 |

|

25 |

25 |

6 |

65 |

|

8 |

4 |

6 |

44 |

|

10 |

5 |

6 |

45 |

|

12 |

5 |

6 |

45 |

|

16 |

6 |

6 |

46 |

Application

Widely used for metalwork, tool making, engineering, model engineering, wood carving, jewellery making, welding, chamfering, casting, burning, grinding, cylinder head porting and sculpting.

WHY CHOOSE US?

1. Cost-effective-Manufacturers produce and sell independently.

2. On-time delivery-Fully equipped, multi-professional machines are processed in the factory for the whole order process.

3. Reliable quality-Careful selection of raw materials, incoming quality control, reliable quality of products.

4. Customization accept-OEM/OBM/ODM

5. Sample-Available.

6. Professional R & D team-New products developed regularly.

7. State-owned enterprise-Reliable credit and abundant capital.

| Payment Terms | L/C, Western Union, D/P, D/A |

| Lead Time | ≤1000 45days ≤3000 60days ≤10000 90days |

| Modes of Transport | By Sea/Express |

| Sample | Available |

| Remark | OEM/OBM/ODM |